HA8108

This article introduces a method for on-site maintenance, calibration, and viewing of gas detectors that are difficult for personnel to access or maintain in gas monitoringApplication of HA8108 Explosion proof Gas Controller. In some applications of combustible and toxic gas monitoring, it is inconvenient or impossible for operation and maintenance personnel to reach the vicinity of the gas detector, such as when the installation position of the gas detector is too high or when the gas detector is installed above the liquid storage tank, making it difficult to perform normal maintenance, calibration, and inspection of the instrument. Under such conditions, other solutions may pose safety hazards to maintenance and operation personnel. Based on the specific usage conditions of users, our company recommends using the gas detection and alarm controller HA8108 with remote monitoring function, which fundamentally solves this problem.

The HA8108 explosion-proof combustible and toxic gas controller can remotely set, display, alarm, and calibrate gas detectors, effectively avoiding the danger of personnel operation and the difficulty of operating gas detectors in the above situations. These remote settings, remote display, and remote alarm functions are fully synchronized with the gas detector in terms of action and display. At the same time, because this controller has obtained ExdIICT6Gb certification, it can work safely in hazardous areas.

1、System design concept

Equipped with sound and light alarmsAppearance of HA8108 Explosion proof Combustible Toxic Gas Controller

Combustible and toxic gas detectors are widely used in process equipment that may contain combustible and toxic gases in industries such as petroleum and petrochemical, chemical, metallurgical, gas, and power. For the detection and alarm equipment of flammable and toxic gases, it is generally in accordance withGB50493-2009, The standard design, installation, and use of the "Design Specification for Combustible Gas and Toxic Gas Detection and Alarm in Petrochemical Industry". The "Design Specification for Combustible Gas and Toxic Gas Detection and Alarm in Petrochemical Industry" has clear requirements for monitoring points of combustible and toxic gases with a density lower than air. The specific provisions are as follows:

GB50493-2009-4.2.3 If the release source of flammable or toxic gases that are lighter than air is located in a closed or partially poorly ventilated semi open factory building, in addition to installing detectors above the release source, flammable or toxic gas detectors should also be installed at the highest point in the factory where gases are prone to accumulate.

According to this standard, it is necessary to install a combustible and toxic gas detector at the highest point in the factory that is prone to accumulation when detecting flammable and toxic gases in light and air. The actual height of common factory buildings is generally5-10 meters, some craft factories may be higher, and there are generally no brackets or other convenient climbing positions on the roof of the factory. Even if there is, there is still a high level of danger for maintenance operators to climb to such a high position. Moreover, maintenance operators need to carry specialized tools for maintenance and calibration operations, which greatly reduces safety and convenience.

For electronic instruments, due to their own characteristics, regular maintenance and calibration are essential to ensure the normal and accurate detection and alarm of the instrument, and to ensure the long-term stable operation of the instrument. Under the above-mentioned process conditions, traditional methods are difficult to ensure normal maintenance and calibration of instruments, and it is even more impossible to regularly check the readings of instruments. Regarding such issuesThe emergence of HA8108 explosion-proof combustible and toxic gas controller fundamentally solves this problem.

The HA8108 explosion-proof combustible and toxic gas controller can remotely set, display, alarm, and calibrate gas detectors, effectively avoiding the danger of personnel operation and the difficulty of operating gas detectors in the above situations. These remote settings, remote display, and remote alarm functions are fully synchronized with the gas detector in terms of action and display. At the same time, because this controller has obtained ExdIICT6Gb certification, it can work safely in hazardous areas.

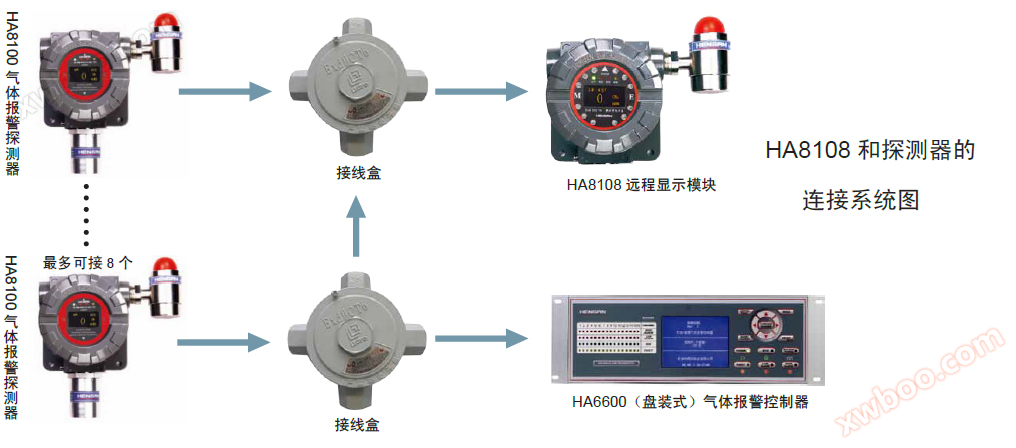

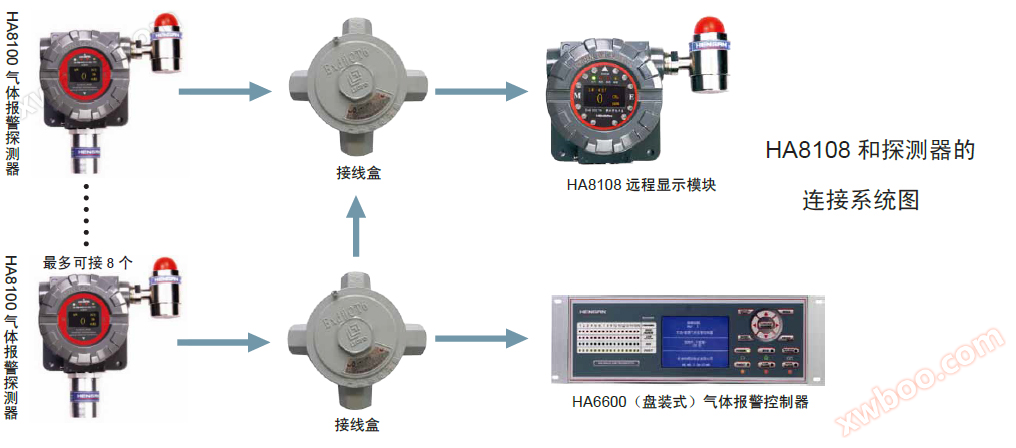

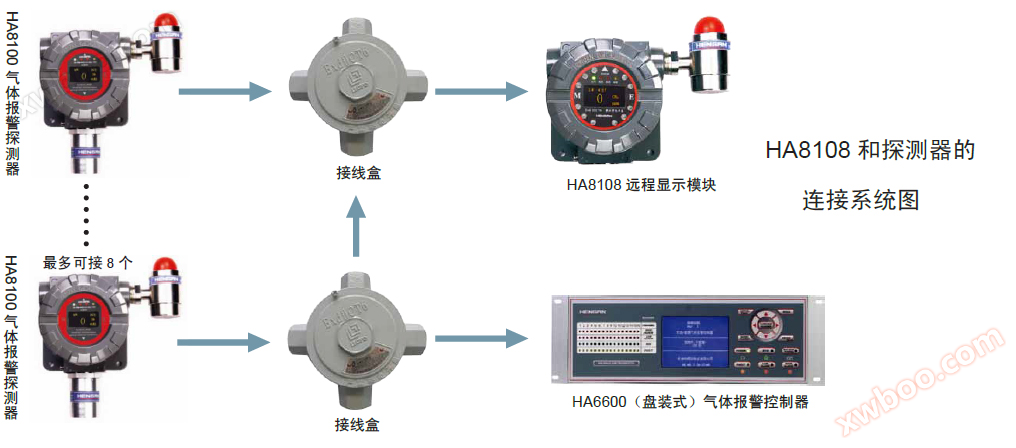

The HA8108 explosion-proof combustible and toxic gas controller communicates with gas detectors through the HABUS bus type digital communication protocol. One controller can control up to 8 gas detectors, with a maximum communication distance of 100 meters, which can meet the requirements of most applications. Digital communication is used between HA8108 and the gas detector. Simply add a communication cable between the junction box and the gas detector. By adding HA8108 to the gas detector and gas alarm controller network without affecting the normal operation of the network, the above monitoring, calibration, and other functions can be achieved.

Connection between HA8108 Explosion proof Combustible Toxic Gas Controller and Gas Monitoring System

The HA8108 explosion-proof combustible and toxic gas controller has high limit and high high limit alarm functions, which can be used in conjunction with our company's HA2200 sound and light alarm to complete on-site sound and light alarm functions; HA8108 automatically highlights the LED, and when an alarm or other information appears, the highlight LED flashes to sound an alarm. The display screen of self luminous OLED is convenient for viewing from all angles in high brightness environments; The high magnetic rod operation avoids the hazardous factors caused by opening the cover in the explosion-proof area.

Principle and System Scheme Diagram of Gas Monitoring System 2

2.1 Principle of HA8108 Explosion proof Combustible and Toxic Gas Controller

As a control device for gas detectors, the main purpose of gas controllers is to achieve remote display and alarm functions of gas detector parameters. As an explosion-proof gas controller installed on site, it also needs to have functions such as remote setting and remote calibration. The most important difficulty lies in improving the stability, communication speed, anti-interference ability, and reducing the bit error rate of communication between the two.

The communication between HA8108 and the gas detector is completed by the HABUS bus type digital communication protocol. HA8108 completes communication between the controlled gas detectors at most every 5 seconds. HA8108 sends query commands to the gas detectors it controls. After receiving the query commands, the gas detectors will provide feedback on the instrument parameters to HA8108. They then take turns sending a set of query commands to the gas detectors they control to complete one round of communication.

selectThe HABUS communication protocol has high stability, with a communication rate of 9600bps baud rate, which can fully meet the communication requirements between devices. Ensured the requirements for anti-interference and reducing bit error rate in device communication.

equipped withSchematic diagram of HA8108 explosion-proof combustible and toxic gas controller

2.2. Application of HA8108 Explosion proof Combustible and Toxic Gas Controller

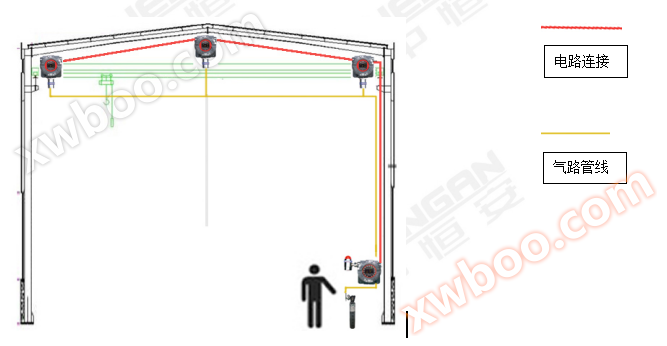

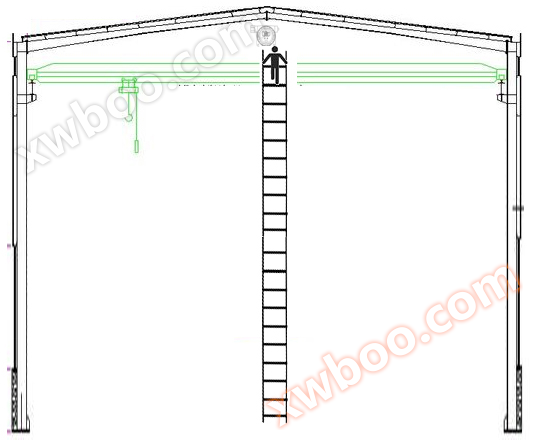

For the detection of flammable and toxic gases that are lighter than air, gas detectors are generally installed at the highest point of the factory where gases are prone to accumulate. Gas detectors require regular calibration and maintenance, which involves the issue of how to maintain them. The traditional approach is for maintenance personnel to carry tools and standard gas cylinders up ladders to maintain them, which poses a high risk and poor operability. The specific method is shown in the following figure.

Schematic diagram of traditional calibration and maintenance work

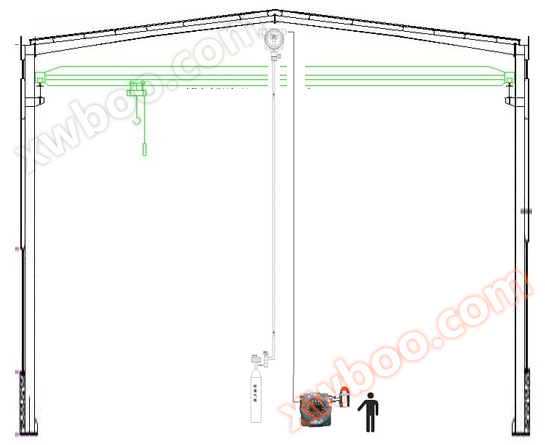

Although this approach can complete the task, it poses significant safety hazards to the operators and has led to many maintenance personnel being unwilling or afraid of such maintenance work. However, the maintenance of instruments is essential for their normal operation, which puts them in a dilemma. In response to this situation, Beijing Zhongheng'an Technology Co., Ltd. has independently developedThe HA8108 explosion-proof combustible and toxic gas controller effectively solves such problems. The working schematic diagram of the gas detection system equipped with HA8108 explosion-proof combustible and toxic gas controller is as follows.

equipped withMaintenance schematic diagram of gas monitoring system for HA8108 explosion-proof combustible and toxic gas controller

As shown in the figure, the gas detector andThe HA8108 explosion-proof combustible and toxic gas controller is connected with shielded cables, while the standard gas can be connected to the gas detector's inlet with a hose. The standard gas is supplied to the gas detector at a flow rate of 0.5~1L/min. Operators can complete the setting and calibration of remote gas detectors by standing on the HA8108 explosion-proof combustible and toxic gas controller on the ground. This operation not only reduces the workload of maintenance personnel, but also fundamentally ensures the personal safety of operators.

Due to the fact that the airflow of standard gas is connected to the gas detector through the air duct, calibration cap, and gas detector, when calibrating the instrument, the air pressure at the inlet can ensure that the standard gas reaches the sensor normally and is discharged from the outlet, thus ensuring that the air inside the calibration cap can be replaced. During regular testing, the air outlet is connected to the atmosphere, and the sensor detects the concentration of flammable and toxic gases in the surrounding air, which does not affect the normal detection of environmental gases.

3、Conclusion

With the increasing awareness of safety among people, there is a greater emphasis on safety in industrial environments. Nowadays, gas detectors, as professional equipment in the field of gas detection, are widely used in various industrial settings. The daily maintenance and regular calibration of gas detectors are the correct practices to ensure detection accuracy and sensitivity. For special application scenarios, the installation location affects the daily maintenance and regular calibration of gas detectors. In this regard,HA8108The explosion-proof combustible and toxic gas controller fundamentally solves this problem.

Since its application on site, the product has been unanimously recognized by customers and has made outstanding contributions to safety production in various industries.